At its core, CNC precision machining involves the use of computer-controlled machines to remove material from a workpiece, creating a desired shape or part. Unlike traditional machining, where operators manually guide the cutting tools, CNC machining relies on programmed instructions to control the movement of the tools and workpieces with high precision.

CNC machines operate on multiple axes, allowing for complex three-dimensional cuts. The primary CNC machine types include milling machines, lathes, routers, and electrical discharge machining (EDM) equipment. These machines can perform a wide range of tasks, such as cutting, milling, drilling, and grinding, enabling the production of components with intricate geometries and tight tolerances.

Technology behind CNC Precision Machining

Here we will discuss the technique behind CNC precision machining;

CAD/CAM Software

Computer-aided design (CAD) software is used to create detailed 3D models of components, while computer-aided manufacturing (CAM) software translates these models into toolpaths for CNC machines. CAD/CAM software plays a pivotal role in programming CNC machines and ensuring accurate replication of designs.

Precision Tools and Toolholders

CNC precision machining relies on high-quality cutting tools made from materials like carbide, high-speed steel, and ceramics. Precision tool holders and collets are essential components that secure these tools in the machine spindle, ensuring stability and accuracy during machining operations.

CNC Controllers

CNC machines are equipped with sophisticated controllers that interpret the programmed instructions and control the movement of the machine components. These controllers ensure precise coordination between the cutting tool and the workpiece, allowing for accurate cuts and intricate detailing.

High-Performance Spindles

CNC machines feature high-performance spindles that rotate cutting tools at varying speeds and with high precision. Spindle technology, including features like variable speed control and tool change mechanisms, plays a crucial role in the overall performance and efficiency of CNC precision machining.

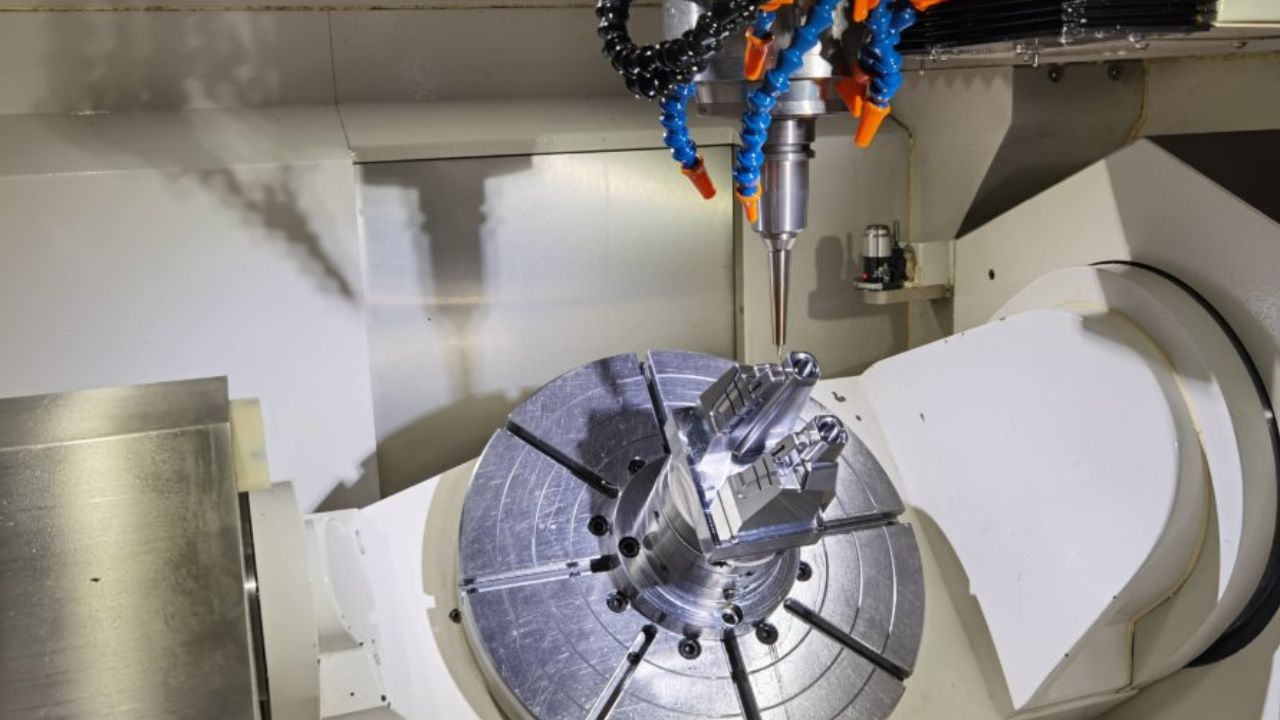

Workholding Devices

Workholding devices such as chucks, vises, and fixtures secure the workpiece in place during machining operations. These devices provide stability and precision, ensuring that the workpiece remains securely positioned and stationary while the cutting tool performs its tasks.

Key Role of Precision Machining

Precision machining plays a pivotal role in modern manufacturing by providing the capability to create intricate and highly accurate components essential for a wide range of industries. Its significance goes beyond simple material removal; precision machining involves advanced techniques and technologies that contribute significantly to the production of high-quality parts. Here are some key roles that precision machining plays in the manufacturing landscape:

Enabling Complex and Intricate Designs

One of the primary roles of precision machining is its ability to enable the creation of complex and intricate designs. Precision machining techniques, including milling, turning, grinding, and electrical discharge machining (EDM), allow manufacturers to produce parts with tight tolerances and intricate shapes that are challenging or impossible to achieve with traditional methods.

Achieving High Levels of Accuracy

Precision machining is synonymous with accuracy and precision. CNC (Computer Numerical Control) machines, equipped with advanced tools and control systems, enable the production of parts with extremely tight tolerances, often measured in micrometers. This level of precision is essential in industries like electronics, where miniaturized components demand high accuracy for seamless integration into electronic devices.

Enhancing Surface Finishes and Quality

Precision machining techniques contribute significantly to enhancing surface finishes and overall product quality. Fine surface finishes are essential in applications where aesthetics, functionality, and wear resistance are paramount. By employing techniques like grinding, lapping, and polishing, precision machining achieves smooth and polished surfaces on machined components.

Supporting Innovation and Advancements

Precision machining plays a fundamental role in fostering innovation and driving technological advancements. By enabling the production of intricate and high-precision components, precision machining opens doors to new possibilities in various fields. Industries such as robotics, aerospace, healthcare, and renewable energy rely on precision-machined parts to develop cutting-edge technologies.

Ending Remarks

Precision machining plays a central role in modern manufacturing by enabling the production of complex designs, ensuring high levels of accuracy and precision, enhancing surface finishes, supporting efficient prototyping, and fostering innovation and advancements. Its contributions are felt across various industries, shaping the development of innovative products and technologies that drive progress and improve the quality of life.